Zinc-Nickel electroplating is an alloy coating deposited from an acid solution that is used for the protection of steel, cast iron, malleable iron, copper, and brass. Zinc-Nickel can also replace cadmium in galvanic interaction applications where the coating is intended to minimize corrosion caused by the interaction of dissimilar metals. The typically thickness varies from 0.0003” to 0.0005”.

Plating Thickness: Ranges from 0.0001 to 0.0012 inches.

Corrosion protection: As a true alloy, Zn-Ni coatings are proven to provide two to three times more corrosion-resistant protection than zinc-only coatings. On the Vickers hardness scale, parts coated with Zn-Ni reach 450, compared to less than 150 for zinc-coated parts.

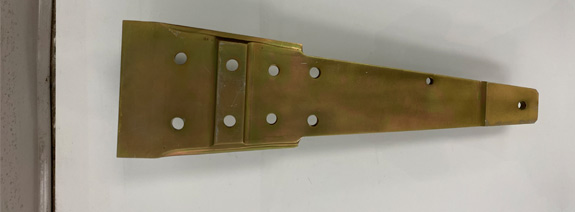

| CLASS 1 | DEPOSITING MIN 5 AND MAX 12% OF NICKEL, BALANCE BEING ZINC |

| TYPE A | WITH COLOURLESS(BRIGHT BLUE)CONV. COAT |

| TYPE B | WITH YELLOW IRIDESCENT CONVERSION COAT |

| TYPE C | WITH BRONZE CONVERSION COATING |

| TYPE D | WITH BLACK CHROMATE CONVERSION COATING |

| TYPE E | ANY OF ABOVE PLUS ORGANIC TOP COAT |

Zinc Plating.

Zinc Plating. Irridite / Alodine

Irridite / Alodine PASSIVATION

PASSIVATION Anodizing

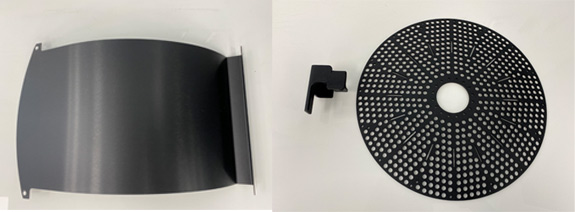

Anodizing Black oxide

Black oxide CADMIUM

CADMIUM PHOSPHATE

PHOSPHATE ELECTROLESS NICKEL

ELECTROLESS NICKEL SILVER

SILVER TIN

TIN Zinc Nickel

Zinc Nickel DECORATIVE / INDUSTRIAL CHROME

DECORATIVE / INDUSTRIAL CHROME ELECTRO PLATED NICKEL

ELECTRO PLATED NICKEL COPPER PLATING

COPPER PLATING Electro – Polishing

Electro – Polishing Ultra Sonic Cleaning and Chemical Cleaning of Metals

Ultra Sonic Cleaning and Chemical Cleaning of Metals Sandblast / Glass-Bead /Brushing / Polishing / Masking / Baking

Sandblast / Glass-Bead /Brushing / Polishing / Masking / Baking Salt Spray Testing / Adhesion and Thickness Testing for plating

Salt Spray Testing / Adhesion and Thickness Testing for plating Powder and liquid Paint

Powder and liquid Paint