Nickel electroplating is a technique consisting of electroplating a thin layer of nickel onto a metal object. The nickel layer can be decorative, provide corrosion resistance, wear resistance, or used to build up worn or undersized parts for salvage purposes. A wide range of metals can be electrodeposited. The technology of nickel electroplating has been extensively developed, particularly through the last five decades, to make possible the efficient production of a broad range of industrial coatings for both decorative and functional applications. Electroplated nickel is commercially important with upwards of 150,000 tonnes deposited annually worldwide. This widespread use reflects the useful properties of nickel as a coating and its versatility. A feature of electroplating is that, by modifying the composition of the electrolyte and the operating conditions, the properties and appearance of nickel can be customised to meet specific needs. Specifications: QQ-N-290 revA, ASTM B 689.

| CLASS 1 | CORROSION PROTECTION |

| CLASS 2 | ENGINEERING USE |

| GRADE A | 0.0016″ |

| GRADE B | 0.0012″ |

| GRADE C | 0.001″ |

| GRADE D | 0.0008″ |

| GRADE E | 0.0006″ |

| GRADE F | 0.0004″ |

| GRADE G | 0.0002″ |

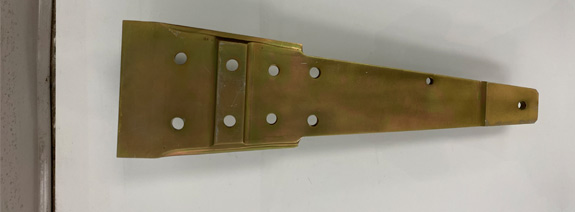

Zinc Plating.

Zinc Plating. Irridite / Alodine

Irridite / Alodine PASSIVATION

PASSIVATION Anodizing

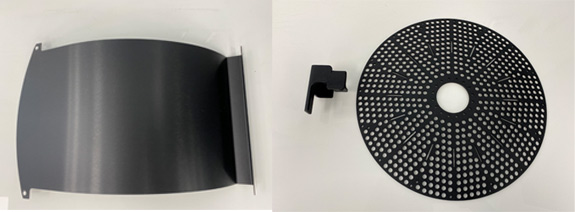

Anodizing Black oxide

Black oxide CADMIUM

CADMIUM PHOSPHATE

PHOSPHATE ELECTROLESS NICKEL

ELECTROLESS NICKEL SILVER

SILVER TIN

TIN Zinc Nickel

Zinc Nickel DECORATIVE / INDUSTRIAL CHROME

DECORATIVE / INDUSTRIAL CHROME ELECTRO PLATED NICKEL

ELECTRO PLATED NICKEL COPPER PLATING

COPPER PLATING Electro – Polishing

Electro – Polishing Ultra Sonic Cleaning and Chemical Cleaning of Metals

Ultra Sonic Cleaning and Chemical Cleaning of Metals Sandblast / Glass-Bead /Brushing / Polishing / Masking / Baking

Sandblast / Glass-Bead /Brushing / Polishing / Masking / Baking Salt Spray Testing / Adhesion and Thickness Testing for plating

Salt Spray Testing / Adhesion and Thickness Testing for plating Powder and liquid Paint

Powder and liquid Paint