Zinc plating involves the electro-deposition of a thin coating of zinc metal onto the surface of another metal object/base-metal. The zinc coating is a sacrificial that prevents rust from reaching the underlying metal surface. Zinc is chosen because of its innate ability to fight corrosion. Zinc Plating can be Clear (Trivalent), Yellow (Trivalent and Hexavalent) and Black. Parts can be baked to avoid hydrogen embrittlement. The thickness for zinc plating can vary from 0.0001” to 0.001” or as per our clients’ request. The expertise developed over the years in addition to the technologies used in constant evolution allows Groupe Altech to remain a benchmark for the quality of work and the service offered to customers.

Olive drab Chromate can be done after Zinc Plating at clients’ request.

Specifications: ASTM B633, PPS 6.2.18, ISO 2081, QQ-Z-325 or as specified by clients with specific requirements.

Materials that can be zinc plated: Steel, Brass and Zinc alloy.

| Type I | As Plated |

| Type II | Coloured Chromate 96hrs (ROHS Trivalent/Hexavalent Not ROHS) |

| Type III | Colourless Chromate ROHS 12 hrs |

| Type IV | Phosphate |

| TypeV | Colourless Passivate ROHS 72hrs,clear HP |

| Type VI | Coloured Passivate 120hrs |

| SC4 | Very Severe 0.001″(FE/ZN25) |

| SC3 | Severe0.0005″(FE/ZN12) |

| SC2 | Moderate0.0003″(FE/ZN8) |

| SC1 | Mild 0.0002″(FE/ZN5) |

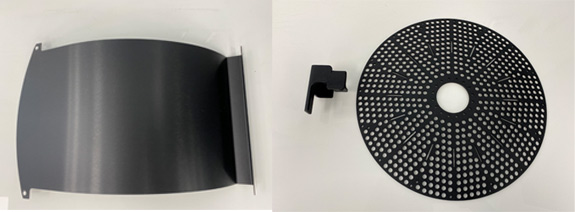

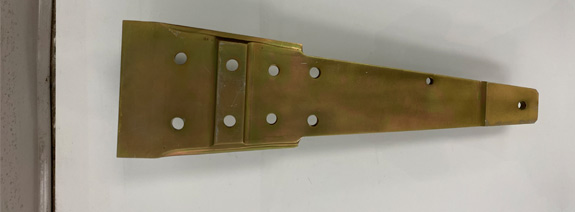

Zinc Plating.

Zinc Plating. Irridite / Alodine

Irridite / Alodine PASSIVATION

PASSIVATION Anodizing

Anodizing Black oxide

Black oxide CADMIUM

CADMIUM PHOSPHATE

PHOSPHATE ELECTROLESS NICKEL

ELECTROLESS NICKEL SILVER

SILVER TIN

TIN Zinc Nickel

Zinc Nickel DECORATIVE / INDUSTRIAL CHROME

DECORATIVE / INDUSTRIAL CHROME ELECTRO PLATED NICKEL

ELECTRO PLATED NICKEL COPPER PLATING

COPPER PLATING Electro – Polishing

Electro – Polishing Ultra Sonic Cleaning and Chemical Cleaning of Metals

Ultra Sonic Cleaning and Chemical Cleaning of Metals Sandblast / Glass-Bead /Brushing / Polishing / Masking / Baking

Sandblast / Glass-Bead /Brushing / Polishing / Masking / Baking Salt Spray Testing / Adhesion and Thickness Testing for plating

Salt Spray Testing / Adhesion and Thickness Testing for plating Powder and liquid Paint

Powder and liquid Paint