Sandblasting can remove paint, rust, and residue from oxidation from materials quickly and efficiently. Sandblasting can also be used to change the condition of a metal’s surface, such as through removing scratches or casting marks. Sandblasting, as a cleaning method, has been widely used for over a hundred years.

Glass beads are solid glass spheres. Due to their high strength, chemical stability, limited thermal expansion, and good flow ability, they are manufactured from colorless glass for several industry purposes and widely used for blasting in order to give rough metals a smooth finish.

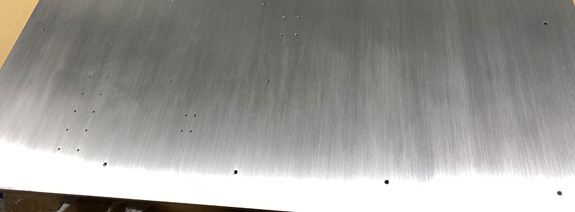

A Brushed or polished surface of metal has a unidirectional satin finish . It is produced by polishing the metal with a grit belt or wheel, then softening it with a greaseless compound or a medium non-woven abrasive belt or pad. Commonly brushed metals include stainless steel, aluminum and nickel. Brushing gives metal a distinctive look as it retains some but not all of its metallic lustre and is given a pattern of very fine lines parallel to the brushing direction. For this reason, it is commonly used for decorative items. Masking is an option prior to any plating process. Post-plating baking consists of baking the part immediately after plating. This can reverse the effects of hydrogen embrittlement, in most cases. General guidelines call for baking the part for four hours at a temperature of 375º F within one hour of plating or as per our clients’ request.

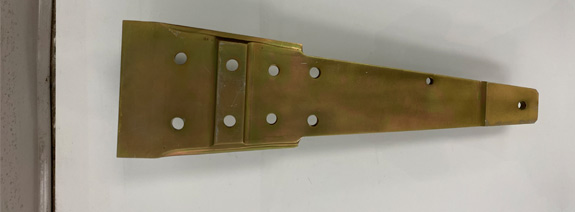

Zinc Plating.

Zinc Plating. Irridite / Alodine

Irridite / Alodine PASSIVATION

PASSIVATION Anodizing

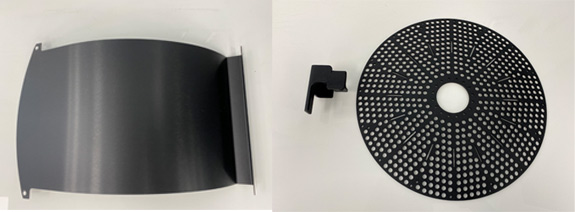

Anodizing Black oxide

Black oxide CADMIUM

CADMIUM PHOSPHATE

PHOSPHATE ELECTROLESS NICKEL

ELECTROLESS NICKEL SILVER

SILVER TIN

TIN Zinc Nickel

Zinc Nickel DECORATIVE / INDUSTRIAL CHROME

DECORATIVE / INDUSTRIAL CHROME ELECTRO PLATED NICKEL

ELECTRO PLATED NICKEL COPPER PLATING

COPPER PLATING Electro – Polishing

Electro – Polishing Ultra Sonic Cleaning and Chemical Cleaning of Metals

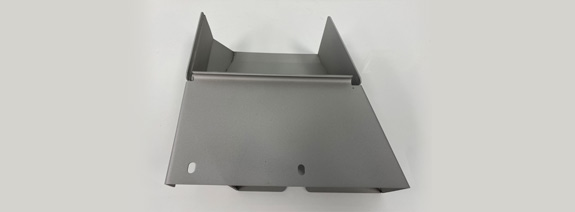

Ultra Sonic Cleaning and Chemical Cleaning of Metals Sandblast / Glass-Bead /Brushing / Polishing / Masking / Baking

Sandblast / Glass-Bead /Brushing / Polishing / Masking / Baking Salt Spray Testing / Adhesion and Thickness Testing for plating

Salt Spray Testing / Adhesion and Thickness Testing for plating Powder and liquid Paint

Powder and liquid Paint